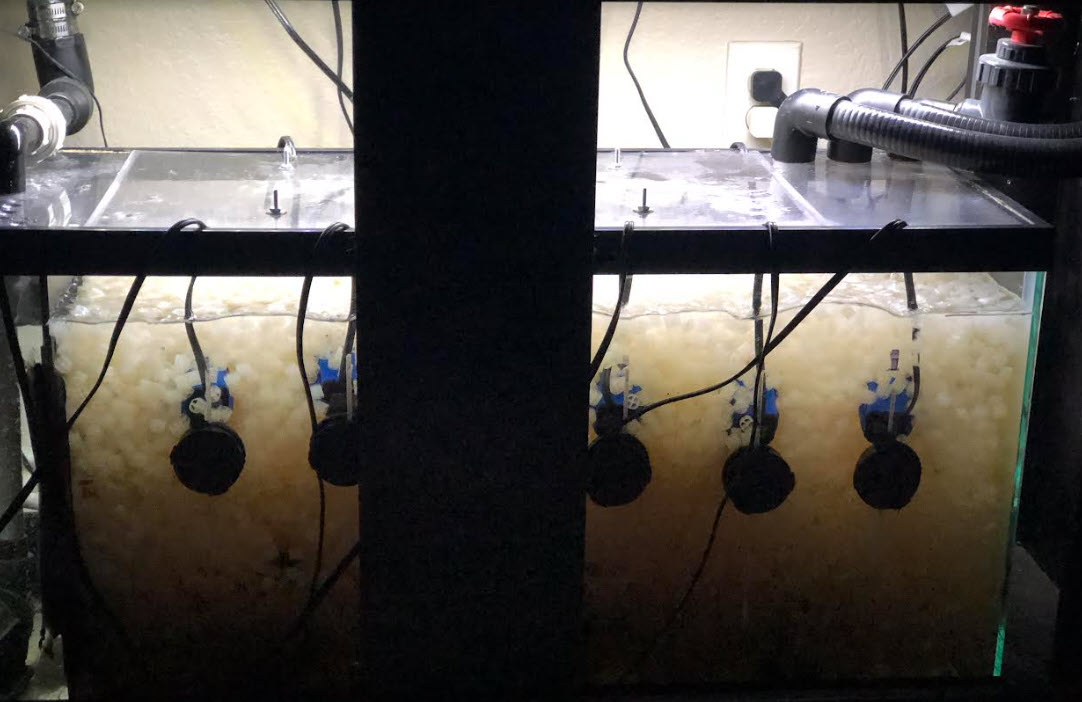

These sump filters use a polyethylene high surface area media (K1 micro, K1, Hel-X, etc.) in a fluidized moving bed set-up. This motion is well illustrated by this sump:

Note the very important circular movement of the K1 media in the sump. It is important to note the following.

.

Many millions of dollars of research in the area of aquaculture have established that fluidized K1 beds are the best type of filter

.

This research is done by Universities. The funding is typically due to the presence of some portion of the aquaculture industry which raises literally billions of dollars worth of fish like tilapia in aquaculture tubs and ponds which need filtration. More monies were added by various European Countries in order to reduce the emissions of waste water plants to the North Sea. Typical papers are “Aquarium Culture of Tilapia”, Rakocy, 2005, and “Design and Operation of Moving Bed Biofilm Reactor Plants for Very Low Effluent Nitrogen and Phosphorus Concentrations”, Rusten, 2007.

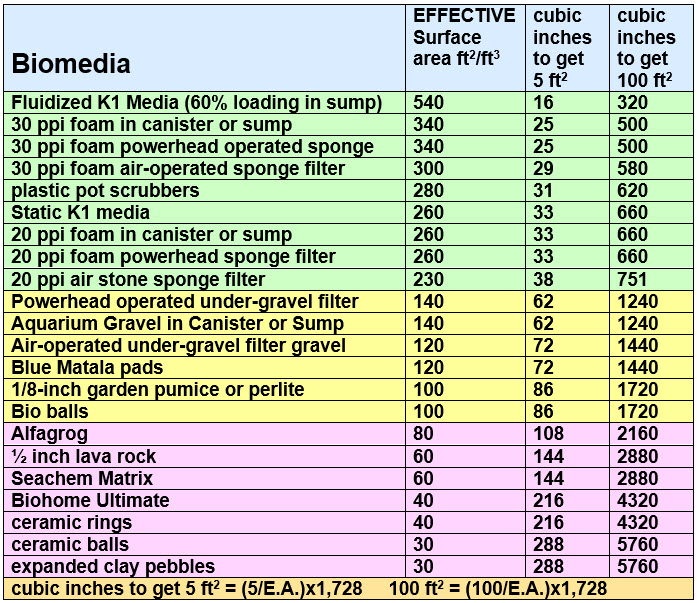

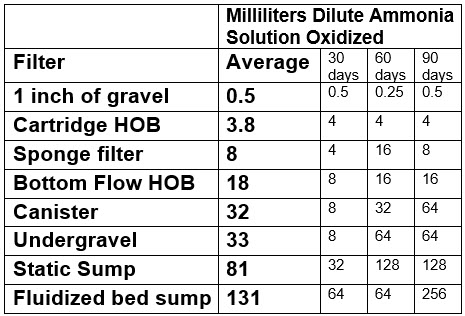

The chart below is based on testing by the author and testing by Universities. If one looks at the top line below one will see that fluidized K1 is 540/340 or 59% better than stationary 30 ppi foam and 540/30 or 1800% better than ceramic balls.

Design of a Fluidized Sump

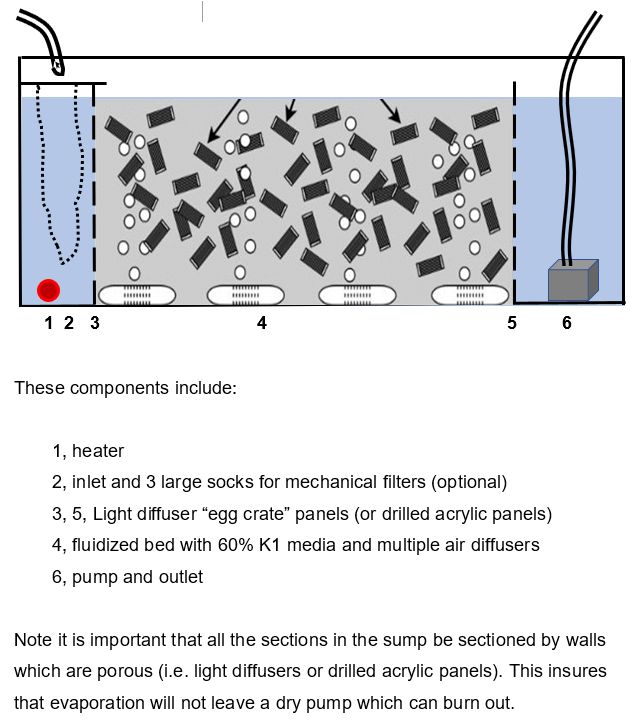

The best design for a fluidized bed sump is:

This design is the best design for an aquarium filter you can have. As a K1 fluidized bed, research has shown it is simply the most efficient filter there is. The design maximizes both the volume of water in the sump and the media volume in the sump. It is easily and rapidly serviced. It maximizes the protection against the pump running dry because of evaporation. It is a very simple design.

Note that fluidized bed K1 media do not trap particles of feces and uneaten food. Rather they simply reduce it in size to small particles the size of a grain of sand. These small particles can be quite distracting in an aquarium. Anytime a K1 fluidized bed is utilized I recommend the use of a mechanical filter. I use undergravel filters which I never clean for all my K1 fluidized bed sumps. Joey uses 100 micron socks which he cleans on a weekly basis. Foam and polyester mats can also be used very successfully.

Replacing the Air Stones with Wavemakers

One little discussed area in filtration is the noise level. Fluidized beds need a whole lot of aeration and bubble to be effective. This amount of bubbles can be noisy, VERY noisy. And large air pumps can be noisy in their own right. If noise is a concern use wavemakers to do the fluidized bed movement.

Six 2.5 watt wavemakers will cost about $40 (less than a large air pump and several high quality air stones). Three wavemakers aimed across the bottom side of a sump and three aimed at the surface from just below the surface on the opposite side of the sump compartment are ideal. This arrangement will give excellent circular flow, great aeration, and a low noise level.

With the wavemaker fluidized bed it is very important to create large amounts of “choppy waves” on the water surface of the sump. These “choppy waves” aerate as well as air stones. An oxygen saturation of at least 80% will give beneficial bacteria the best environment for doing their work.

Light diffusers (white “egg crate” plastic) are a common element in many sumps. But the light diffuser plastic has become very thin and weak as of late. So for fluidized sump builds one should use acrylic panels with many holes drilled into it. It is much stronger than the light diffusers and the K1 can’t get through it if the drilled holes are smaller than the K1 diameter.

It is important to use at least two big socks for the pre-filter if you use socks. Socks can plug up quickly when used with a heavily stocked aquarium. Polyester mats are much preferred over socks as they do not plug up as fast and do not require the constant maintenance of socks. I use NO mechanical filtration in my K1 fluidized bed sumps but all of the associated aquariums have undergravel filters which act as mechanical “polishing” filtration.

The Mechanics of Fluidized Beds in Aquarium Sumps

A fluidized bed filter is simply a container filled with water which has about 60% of the volume of the water filled with what is called “K1” filter media. This K1 filter media is from Kaldnes in Europe originally, thus the name. But many copies and cheap Chinese knock offs can be found on the internet.

Movement of the fluidized bed media is typically accomplished by air bubbles. A schematic of a typical fluidized bed filter or more properly called a mixed bed bioreactors, a moving bed biofilm reactor or a MBBR, is:

There are several do-it-yourself versions of them on YouTube. Try Joey (the King of DIY aquariums). He’s got a great book about DIY aquariums that is only $25 for the electronic pdf version. It has a fluidized bed design in it.

If one doesn’t want to do a do-it-yourself sump for a fluidized bed one is pretty limited. There are some very expensive but very good “reactors” put out by Bashsea which do a good job.

Joey has some “DIY bottle filters”, both with fluidized beds and with regular media. Avoid this DIY bottle design in all its variations. The flow through the bottle is too low to be an effective filter. An air operated filter needs a lift tube to move water through the filter. Note that Joey apparently read my analysis of his bottle filters and changed the design in April of 2023 to a design which has flow through the bottle.

Avoid the small in tank Ziss Bubble Bio Moving Bed Filter, like the DIY bottle filters this filter has no flow through it so it has little effect in the aquarium.

One can also buy any one of several commercial static sumps designs and convert them to fluidized bed sumps quite easily.

Virtually all fluidized bed designs use bubble aeration to move the media. It is important to stage the air stones in such a way as to get the media moving in a circular fashion, up with the bubbles, across the top of the filter, down the opposite side of the filter, and across the bottom.

The aeration provides the oxygen required for the beneficial bacteria to work at their best potential and the design has no dead spots where the biofiltration slows because of lack of oxygen.

How the Aquarium Fluidized Bed Works

The key to this filter is the inside of the K1 media. Inside the media a thin filmy brown “gunk” builds with time. This brown “gunk” is several different types of beneficial bacteria in several forms of “biofilm”.

Because of the rapid movement of the media the brown “gunk” get the ideal fast flow rate required for optimum biofiltration. Also, the movement knocks out any excess brown “gunk” and prevents clogging of the media. I.e. this design is “self-cleaning”.

The best media for a fluidized bed for a home aquarist is the K1 plastic media in all its many variations. This media needs to be purchased in bulk as it is ridiculously expensive in small quantities. This media is typically loaded as to fill 60% of the volume of the water in the filter bed.

Alternatives to K1 Media

There are several other product besides K1 style media marketed for fluidized beds. They all do not work well in a home fluidized bed filter. Stick with only K1 media or similar designs made of white polyethylene plastic.

Poret®aqua Media is cubes of urethane foam marketed as a fluidized bed media. Poret®aqua Media is NOT a good media for fluidized beds. First off there is no flow through the media, which makes it very poor. Then there is the problem that the plastic which makes up the media, namely urethane, is heavier than water. So once the bubbles inside the foam dissipate (like in a few weeks) the foam media sinks and no longer circulates.

There is a type of media out of Germany called the “Mutag Biochip” which is a polyethylene foam disc. It will work about as well as K1 in a fluidized bed but it is somewhat difficult to keep in motion without it stacking up and stopping biofiltration. It can be made to work very well in commercial operation where there is constant engineering support. We do not feel that it is good for an aquarium fluidized bed. Note it cannot work in a static bed because of the tendency of the disks to stack with one another, like the chips in a box of Pringles.

Fluidized Bed Myths

Note that there are a lot of myths about fluidized bed filters. The chief one is that “old bacteria” get knocked off the media so robust “young bacteria” can grow. Bacteria reproduce by binary fission, one bacterium splits into two bacterium. So, there is no such thing as “old” bacteria.

What does happen is that the center of the K1 media becomes filled with a wispy soft brown gunk. The flow of water through this gunk is perfect for beneficial bacteria. As is the oxygenation provided by the air bubbles or the surface agitation. And the whole apparatus can’t sludge up and stop flow because of its design. When the gunk moves out too far into the current in the K1 and starts to close down the holes, the excess gunk gets knocked off and the holes don’t plug up. Thus the great filtration of a fluidized bed sump.

Another myth is that the fluidized bed K1 media needs to have several weeks of submersion before it can form a biofilm which weights it down and allow it to circulate in the sump. In truth there will be small bubbles in the K1 media when it is first put into the sump. These bubbles make the K1 float and refuse to circulate in the sump. The bubbles dissolve over a span of two to five weeks and the K1 will begin circulating.

Still another myth is that fluidized beds take much longer to cycle than standard media such as stationary ceramic media. Testing showed that the fluidized K1 cycled just about as fast as any other media. Depending on the bioload, K1 can take many months to get brown gunk inside it. But brown gunk is not necessary for ammonia oxidation. A clear film rapidly develops on the K1 which does ammonia oxidation quite well.

Research on Fluidized Beds

As we stated above.

Many millions of dollars of research in the area of aquaculture have established that fluidized K1 beds are the best type of filter by a factor of 59% to 1800% on a cubic inch per cubic inch of filter basis.

.

Now many will question this claim. So we have put together some very boring research on what the science says about this. If you are an OCD nerd like the author, read on:

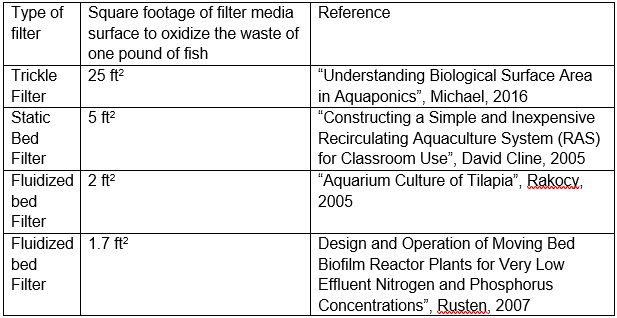

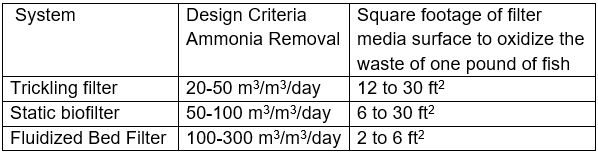

In support of this claim here are four references on ammonia oxidation by the type of filter.

The difference between these reflects the difference in efficiencies for a fluidized bed over a static submerged bed filter. A fluidized bed filter is just two to three times more efficient than a submerged static media filter. This is because of the rapid speed with which the water circulates through the center of the fluidized bed media and the large effective surface area of the K1.

“Production in Intensive and Recycle Systems”, Muir et. al., 2000 is a useful reference. It compares the capabilities of the various filter media systems.

This corresponds very well with the first four references.

Still another similar reference is “Nitrification in Moving Bed and Fixed Bed Biofilters Treating Effluent Water from a Large Commercial Outdoor Rainbow Trout RAS”, Suhr, 2010:

“Expressed as volumetric total ammonia-N (TAN) removal rate, the moving bed filters had significantly higher removal rate (231 ± 17 g N−1 m−3 d−1) compared to the fixed bed filters (92 ± 2 g N−1 m−3 d−1).”

Suhr set up four identical capacity filter sumps. Two with moving bed (MB) and two with fixed bed (FB) media. The moving beds had 2.5 times the filtration capacity of the fixed beds, confirming the data of the previous five references. This makes six references confirming the superior abilities of a fluidized bed filter.

This assessment of fluidized beds (to a fish farmer these are “Mixed Bed Bioreactors”, “Moving Bed Biofilm Reactors” or MBBRs) is confirmed by the very recent book “Recirculating Aquaculture Systems: A Guide to Farm Design and Operations”, Davison, 2018:

“The final filter to discuss is the mixed bed bioreactor (MBBR), the most widely adopted biofilter for large scale RAS operations. The MBBR has been adopted by most RAS designers and operators because of its efficiency, reliability, predictability and low cost.”

Most of the research on fluidized beds in aquaculture has been done in just the past twenty years so one needs to use relatively recent references.

Note that a fixed bed filter with 30 ppi foam in it will be about 63% as good as a fluidized K1 bed. The K1 is loaded 60% at 900 square feet per cubic feet while the foam is 100% loaded at 340 square feet per cubic feet. 60% of 900 is 540 square feet per cubic feet of filter. 340/540= 0.63. The foam will typically need some periodic maintenance and partial cleaning while the fluidized K1 never needs maintenance. This is why MBBRs are so popular in aquaculture.

Better Filters

Note that there are some filtration systems which, if perfectly set up and heavily maintained, will surpass K1 fluidized beds. Sand filters and bead filters will outperform K1 fluidized beds by a factor of two to three. But these systems are only suitable for public aquariums where there are several people in the maintenance department who spend all their time maintaining the expensive systems. These systems are not for home hobbyists.

There are also some small fluidized sand bed “canisters” of sort which can do a very good job, outperforming Fluidized K1. But they are tricky and difficult to set up. We cover these in more depth in this article:

8.7.1. Sand Filters

Sumps in More Depth

For more information on other types of sumps click on these links:

8.6.1. Sumps in Depth

8.6.2. Static Submerged Media Sumps

8.6.3. Trickle Filters

8.6.4. Wet-dry Sumps

8.6.6. Do-it-yourself Sump

8.6.7. Foam Sump

Note that many beginners are concerned about how to flow the water to a sump. The common refrain is “my aquarium isn’t drilled, how does the water get to the sump?” Click on this link to get some ideas:

14.7. Overflow Devices

.

Return to Filter Menu

Return to Sump Menu

.

Aquarium Science Website

The chapters shown below or on the right side in maroon lead to close to 400 articles on all aspects of keeping a freshwater aquarium. These articles have NO links to profit making sites and are thus unbiased in their recommendations, unlike all the for-profit sites you will find with Google. Bookmark and browse!

.

Dave says

In reply to Michael ….. I would add four or five commercial fifty gallon undergravel filters. However many the dimensions allow.

Michael says

Any suggestions on DIY undergravel filter for a 900-gallon 130 x 48 x 36″ tank?

Dave says

In reply to Jimmy ……… Ideally 100%. But 50% works well so don’t obsess over it.

Jimmy says

What percentage of the K1 should be in motion in order for it to be the most effective media?

Dave says

In reply to Tyler ….. There are about four things that need to be done to “leak proof” any and all sumps. These action can be found under “leak proofing” in the following article: https://aquariumscience.org/index.php/8-6-1-sumps-in-depth/

Tyler Davis says

I was thinking of getting a fluval canister filter until I came across your site. I would like to avoid the headache of a water leak and have decided to try the fluidized bed. Is there any tips that I can use to avoid a water leak?

I was going to shoot for a 40g breeder for a 120g aquarium

Dave says

In reply to Luis ….. 1, No need to pump air into the evaporation tub, assuming you are moving the K1 via bladed pumps.

2, the more media you have the better. But it would be better if you replaced the bioballs with stationary K1

3, That will filter about ten pounds of fish so yes it should do its job and give you clear water.

Dave says

In reply to Luis … Yes, you re doing it correctly. Not many get it right.

Luis A says

Hello again,

My previous question remain, however, I have ran the calculations based on the adult size of the desired fish and I come up with a MBW of 4591g or 10.12 lbs.

If I understand correctly I will need 1012 sf of media to handle this bio load.

25 lt of K1 in a 13.8 gallons sump tub gives me 996 sf of media.

6 pieces of poret foam 20 ppi 3” thick in a 4” x 10.5” basket gives me 114 sf of media.

For a total of 1110 sf of media, leaving me an excess of 98 sf of media.

Am I looking at this correctly?

Thank you,

Luis

Luis A says

Hello,

I ordered a 120 G aquarium with a sump. The sump consists of:

1) filter tub (200 micron sock), this overflows into a

2) baffle tub with 5 baskets that are supposed to be filled with 5L of bio-balls, but now I will instead use 20ppi Poret foam inside each basket. Heater and two Sicce pumps inside this tub. The 5L of bio-balls I will put into media bags and place inside the filter tub.

3) evaporation tub, connected to baffle tub. 13.8 gals recommend usable capacity. I plan to flow some of the water from one of the Sicce pump (714 GPH) into this tub and place 25 liters of Kaldnes K1 media inside of it (roughly 60% of volume).

A few questions:

1) do I need to pump air into the evaporation tub as well?

2) utilizing the bio-balls inside the filter tub makes any sense?

3) will 25L of K1 combined with the other bio-media provide clear water on a heavily stocked 120G aquarium?

Thanks!!

Dave says

In reply to Gunter …. Technically all my tanks still have mechanical filtration in that they combine a sump with an undergravel filter. The undergravel acts as a mechanical filter which never needs to be cleaned. I can see where just a fluidized sump will give fine particles in the water.

Gunter says

Hey Dave, your site is what I was searching for years! All other stuff is just parroting. I shut down my 1500l Discus tank 2 years ago. With this information I probably wouldn’t had to. Just one question. If I spared the mechanical filtration wouldn’t I have a lot of very small stuff in my water over time. I guess over time a lot fine stuff will accumulate in the fluidized sump and because it is always in move it will and up in the tank. Used a Theiling Rollermate before.

Dave says

Buy the cheapest one.

Raj says

Thanks for your reply Dave.

As of this point, I am trying to decide between K2 media ($33 on eBay for 1 cu ft or 28 liters) versus K+ media ($118 on the net, for 25 liters)

Should I pay around 4 times more?

I mean I could pay that; it is not “unaffordable” since I will need only around 25 liters. BUT, you get what you pay for, and I have been burnt many times in the past for being “el cheapo”! LoL

K2 specs:

Diameter = 10mm

Length = 7mm

Total surface area = > 1000m2 per m3

Protected surface area = ?? (Not listed, and unable to find that on the internet)

K+ specs:

Diameter = 10.2mm

Length = 8mm

Total surface area = 1,350m2 per m3

Protected surface area = 1,025m2 per m3

Upon googling, it seems to me that protected surface is very important. Some articles:

https://www.linkedin.com/pulse/smallboss-mbbr-media-agnes-che-mbbr-bio-media-bio-blok-

https://www.waterworld.com/drinking-water/treatment/article/14039775/mbbr-carrier-media-what-do-i-really-need

-Raj

Dave says

In reply to Raj …. In theory the smaller holes should clog up. In practice I’ve seen no difference in performance over time with either the size or the particular design of the K1 type media in an MBBR. One reader had the small hole stuff plug up in a stationary bed.

Raj says

Man! I wish I had come across your article when I setup my sump filter a few years ago with Porets. 🙁 I talked to Mr. Tanner (very nice guy, BTW) and on his advice, bought his Poret®aqua Media instead of K1. Anyway, your article lists the pitfalls of going that route nicely.

I am about to swap them with K1. But when I look at the internet, there are so many designs competing with the original “4-spoke K1 design”. Some have Lego type + in the middle surrounded by circles, others have more concentric circles. Makes me wonder if the free space inside matters in some way.

Isn’t more surface area in these newer designs better?

What if the free space inside is too small for the bacteria to get “flushed out”, if that is a thing in moving media filters anyway.

I would love to hear your thoughts!

-Raj

Dave says

In reply to Matt … Yeah, a while back I got some wavemakers that were very open in the back an let the K1 interfere with the blades. I had to cover the wavemakers with a mesh to prevent the K1 from getting in. And don’t try for perfection. If you can get 75% of the K1 in motion you are doing well. It will take some playing around to optimize the movement.

Matt says

Hey Dave, I’m having trouble getting my k1 to move. When I use wave makers the k1 gets sucked up into the inlets. Now trying air but haven’t size the air pump very well. The sump is approx 600mm wide 500mm long and 450mm deep. Any tips?